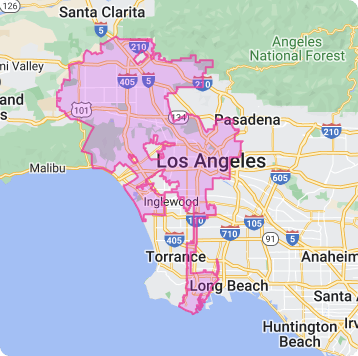

Resources & Guides / Roof Coating Guide for Los Angeles County

Roof Coating Guide for Los Angeles County

Flat Roof Density by Square Footage: High

Estimated Population: ~10+ million people

Common Flat Roof Surface Types: MBR, TPO, Concrete, BUR, Metal

Regulatory Considerations: Title 24, VOC Limits, Class A Fire Ratings

Average Annual Precipitation: ~15 inches

Average Annual Humidity: ~65%

Natural Disaster Risk: High; earthquakes and wildfires

Elastomeric Roof Coatings

In Los Angeles County, these types of water-based elastomeric roof coatings can be ideal due to their flexibility, which can also be important for the integrity of the roof surface during earthquakes. These coatings can be made to provide water resistance and protect the roof surface from the occasional heavy rainfall. Their elasticity helps prevent surface cracking across varying temperatures, making them durable over time. Reflective elastomeric coatings adhere to California's Title 24 regulations, which emphasize energy efficiency and building resilience.

Product recommendations: Deck Flex T2424 Roof Coating

White Roof Coatings

These are the most reflective types of roof coatings and favored in Los Angeles County for their high solar reflectivity. This quality significantly reduces building cooling costs and mitigates the urban heat island effect, aligning with California's Title 24 energy efficiency requirements. The reflective nature of white coatings also potentially lowers fire risks during wildfire seasons by reducing roof surface temperatures, making them a good choice for both energy conservation and safety.

Product recommendations: T2424 White Roof Coating

Roof Coating Tools & Accessories

To make sure you get a uniform application of elastomeric or white roof coatings, consider using professional-grade sprayers, rollers, and brushes. Surface preparation is also key. Additionally, seam tape and patching fabric are important for preparing surfaces and addressing any cracks or seams prior to application. Moisture meters and infrared thermometers can be used to assess the roof's condition and ensure the surface is dry and at an optimal temperature for coating. Proper tools not only facilitate a smoother application process but also enhance the long-term performance and durability of the roof coating.