ANSI/BHMA A156.3-2014 Grade 1 Standards

Exit devices and panic hardware certification requirements for commercial applications

Last updated: September 25, 2025

Overview

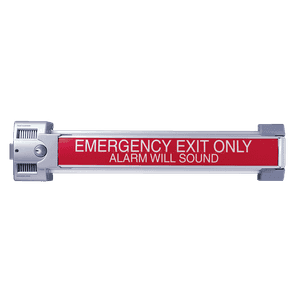

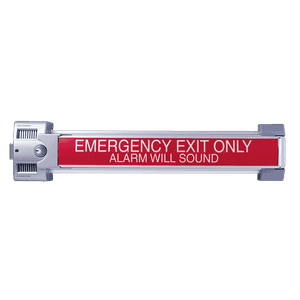

ANSI/BHMA A156.3-2014 is the American National Standard for Exit Devices, developed by the Builders Hardware Manufacturers Association (BHMA). This standard establishes performance requirements, test methods, and operational characteristics for panic hardware and fire exit hardware used in commercial buildings.

Grade 1 certification represents the highest level of durability and performance, requiring products to withstand 500,000 cycles of operation, making them suitable for high-traffic commercial applications where reliability is critical for life safety.

Grade Requirements

ANSI/BHMA A156.3 defines three grades of performance, with Grade 1 being the highest:

| Grade | Cycles Required | Typical Application | Force Requirements |

|---|---|---|---|

| Grade 1 | 500,000 | High-traffic commercial | 15 lbs maximum |

| Grade 2 | 250,000 | Light commercial | 15 lbs maximum |

| Grade 3 | 100,000 | Residential | 15 lbs maximum |

Grade 1 Specific Requirements

- Must maintain consistent performance throughout 500,000 cycles

- Operating force cannot exceed 15 pounds at any point during the test

- Latchbolt must project at least 1/2 inch when door is closed

- Device must operate smoothly without binding or excessive wear

- Outside trim must withstand 250,000 additional cycles

Testing Criteria

Cycle Test

The device must complete 500,000 cycles of operation on a test door. Each cycle includes full depression of the touchpad or crossbar, door opening, and return to the latched position. The test is conducted at a rate not exceeding 25 cycles per minute.

Operational Force Test

- Maximum 15 pounds force to actuate the device

- Force measured at multiple points along the actuating bar

- Test performed before and after cycle testing

- Force must remain consistent throughout service life

Additional Test Requirements

- Finish durability: Salt spray test for 96 hours minimum

- Security test: Withstand 250 pound-force pull

- Dogging test: 10,000 dogging/undogging cycles if applicable

- Temperature test: Operation from 0°F to 120°F

- Vertical rod test: 100,000 cycles for top and bottom latches

Applications

Grade 1 exit devices are typically required or recommended for:

High-Traffic Areas

- Airport terminals

- Convention centers

- Sports arenas

- Shopping malls

- Transportation hubs

Critical Facilities

- Hospitals and healthcare

- Schools and universities

- Government buildings

- Data centers

- Emergency shelters

Compliance Considerations

When specifying Grade 1 exit devices, consider these compliance factors:

- ADA compliance: Maximum 5 pounds operating force for accessibility

- Fire rating compatibility: UL 10C listing for fire-rated assemblies

- Code requirements: IBC, NFPA 101, and local building codes

- Windstorm ratings: Miami-Dade or TDI approval in hurricane zones

- Security features: Delayed egress or controlled access options

ANSI/BHMA A156.3 Grade 1 Certified Products

Was this guide helpful?

Your feedback helps us improve our resources and guides.